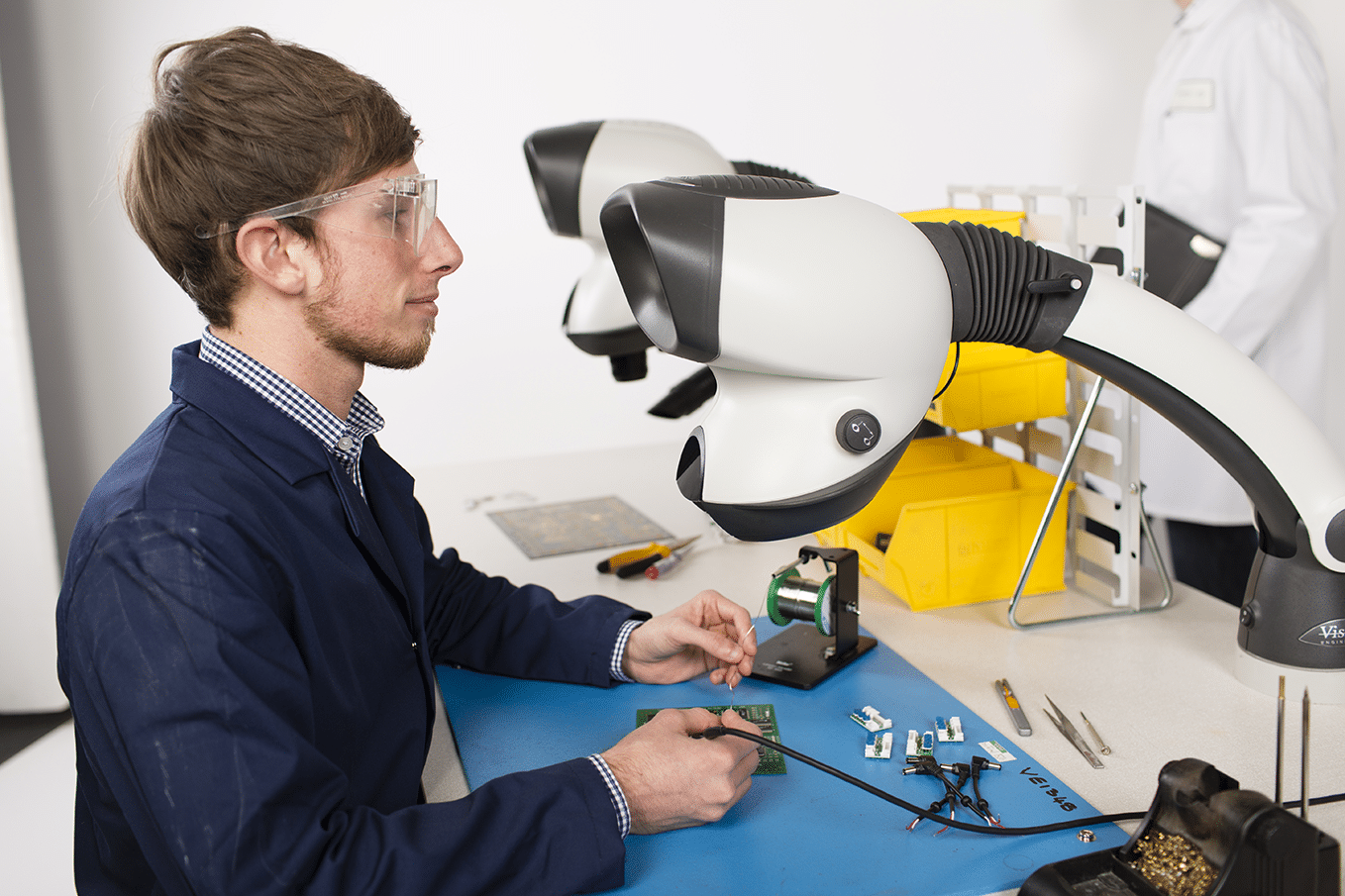

World Leaders in ergonomic microscopy, digital 3D visualisation and metrology solutions

Our pioneering eyepiece-less stereo microscopes, digital 3D inspection systems and metrology systems enable our customers globally to improve quality, efficiency and productivity.

Lynx EVO

Work better, for longer, with this award winning ergonomic stereo microscope.

Mantis

Eyepiece-less inspection systems help keep employees safe from cross contamination.

WHAT OUR CUSTOMERS SAY

We have used a Mantis microscope in our Dental Laboratory for over a decade now. It is ergonomic, reliable and well-suited to enhancing the accuracy and quality of our Crown & Bridge work. We currently have three Mantis in our laboratory and we consider this to be essential equipment. We could never go back to using just loupes for fine detail work and quality checking. Excellent, well-engineered equipment!

Excellent inspection/rework options and superb customer service. Highly recommend Mantis.

As a result of its generation of high-resolution 3D images, the use of our DRV-Z1 is now helping to ensure the quality of our PCBs and assisting us in reducing our already low rework and scrap levels.

Hawk is the ideal piece of metrology equipment for us. It is easy to use and flexible enough to gauge nearly all of our components. The reporting capability allows me to capture a data file for every component we measure, which is vital for component traceability.