In the fast-paced realm of electronics manufacturing, precision, and efficiency are paramount. The microscopic intricacies of electronic components demand cutting-edge tools that not only provide exceptional clarity but also enhance the overall workflow. Vision Engineering’s Mantis and Lynx EVO range of stereo microscopes and the EVO CAM digital microscope have emerged as the undisputed leaders in this field, redefining the standards for inspection and setting a new benchmark for electronics manufacturing.

Improve user productivity during physical inspection and reworking

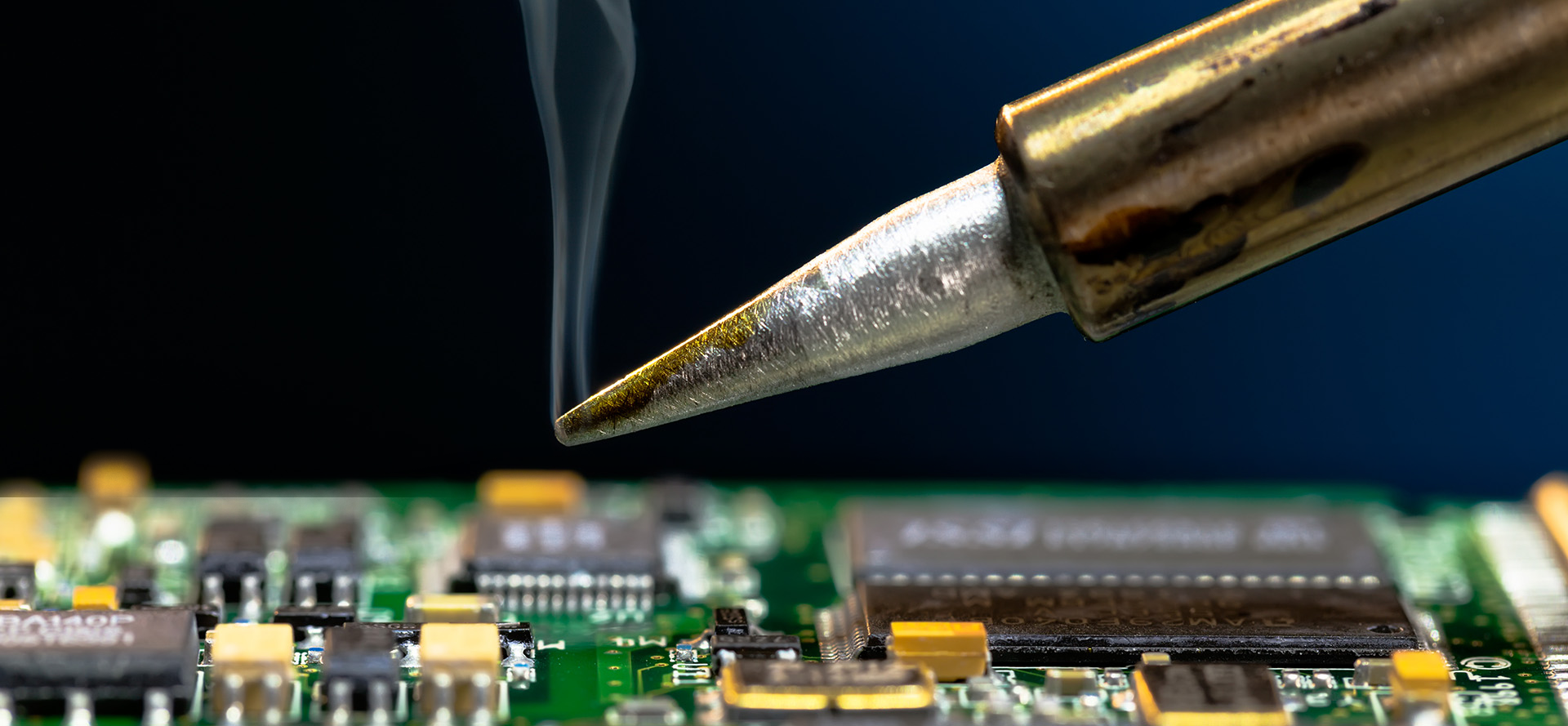

One of the key factors contributing to the Mantis and Lynx EVO microscopes’ number one status is their innovative design, specifically engineered to address the unique challenges faced in electronics manufacturing. One challenge is how to create user comfort when using a stereo microscope for extended periods of inspecting or reworking.

With Vision Engineering’s eyepiece-less microscopes, users experience greater comfort due to the viewing distance from the microscope to the user’s eyes. This distance allows access to ambient light, reducing iris activity when working, therefore minimizing eye fatigue. The ergonomic design of both microscopes ensures user comfort during prolonged usage, reducing tiredness and improving productivity.

This enhanced view also helps users to understand the shape and form of the subject, and the position of the tools they are using to work on the sample. Sample manipulation using tools can be carried out with higher levels of accuracy and confidence.

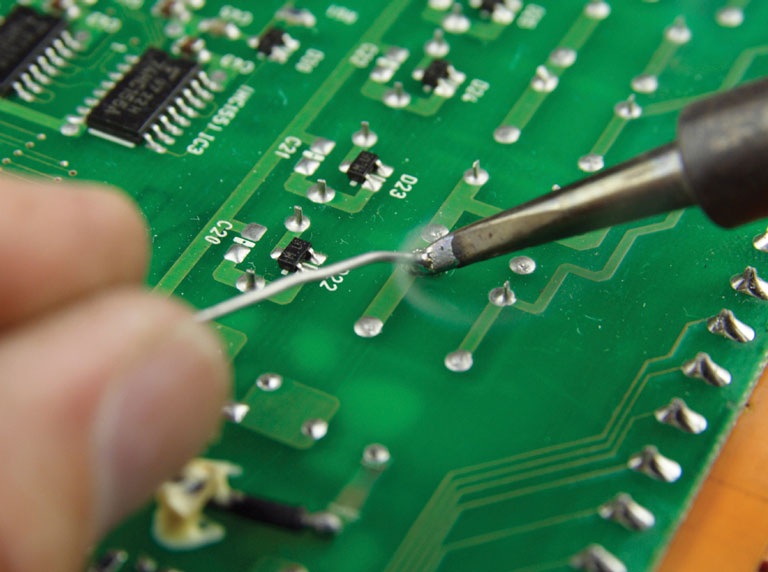

See the details during component and solder joint inspection

Visual inspection of defects including misaligned, wrong, or missing components, solder defects, poor wetting, pad lifting, and fillet tearing can be effortlessly achieved with Mantis, Lynx EVO, and EVO CAM systems. Stereo microscopes, with their 3D view, offer the benefit of revealing surface finish and textures which can indicate poor soldering quality and other defects while digital microscopes offer a rapid, clear monitor view of defects.

Crystal clear images due to high-quality optics

Advanced optics deliver crisp, distortion-free images across a wide area, allowing operators to identify defects, solder joints, and other imperfections quickly. In electronics manufacturing precision is non-negotiable. With Mantis, Lynx EVO or EVO CAM microscopes the quality optics gives these systems a significant advantage over the competition.

Objective lens ranges to suit the level of magnification needed

Fine pitch components are common in modern PCBs, and their inspection demands a level of precision that can only be achieved through magnification. Optical systems are available with fixed or zoom magnification ranging from 3x to 240x and digital systems with magnification up to 725x.

When high magnification is needed along with long working distances, Mantis can be fitted with a super long working distance lens. These are available in both 6x and 8x which will allow for rework or soldering tools to easily fit between the lens and the component.

See more details with a range of lighting options

Mantis features 5 different illumination modes, giving you maximum control over lighting your subject. This ensures you achieve the best possible shadow-free illumination of your sample for the best quality inspection and manipulation. Mantis is fitted with two banks of LEDs which can be set for synchronized or independent operation. Controlling each bank independently gives you the option to add shadow detail, enhancing your 3D understanding of the subject. Additionally, it helps prevent unwanted reflections, which can hide subject details.

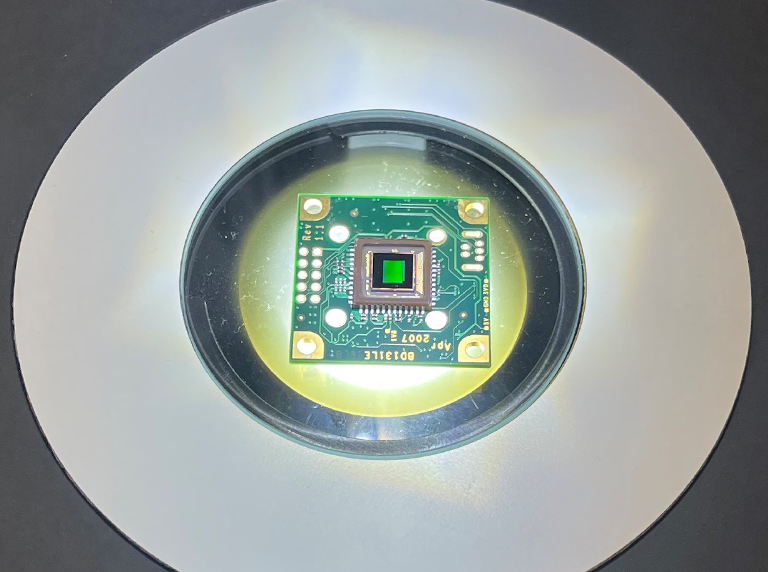

Transmitted illumination for enhanced inspection of transparent subjects

Lighting from below enables more accurate inspection of through holes, transparent, translucent, and perforated subjects. Mantis, Lynx EVO, and EVO CAM systems can be mounted on stands that support sub-stage lighting, lighting that is located below the component.

Enhance the examination of electronic components and solder joints with UV illumination

UV illumination is used to detect flux residue, cracks, fractures, conformal coating defects, identification of counterfeit components, and other defects sensitive to UV light. Mantis and EVO CAM systems are equipped to inspect using UV illumination. Mantis ERGO and PIXO systems can easily switch from white to UV illumination with a simple click and EVO CAM systems can easily have the addition of UV lighting added to the ring light.

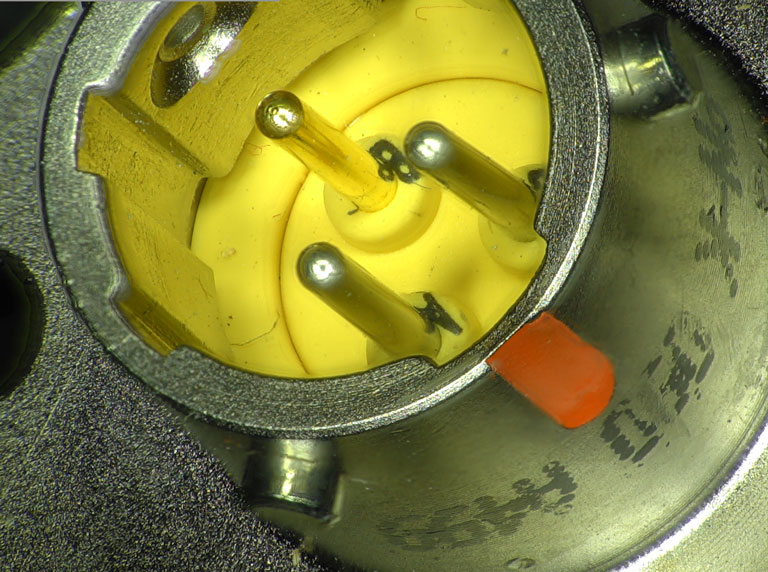

Inspect component cavities with episcopic illumination

Mantis can be fitted with an episcopic illuminator ensuring that a cavity is fully lit by sending light along the same path that the Mantis viewer sees it. If the viewer can see it, it is illuminated, improving inspection capabilities.

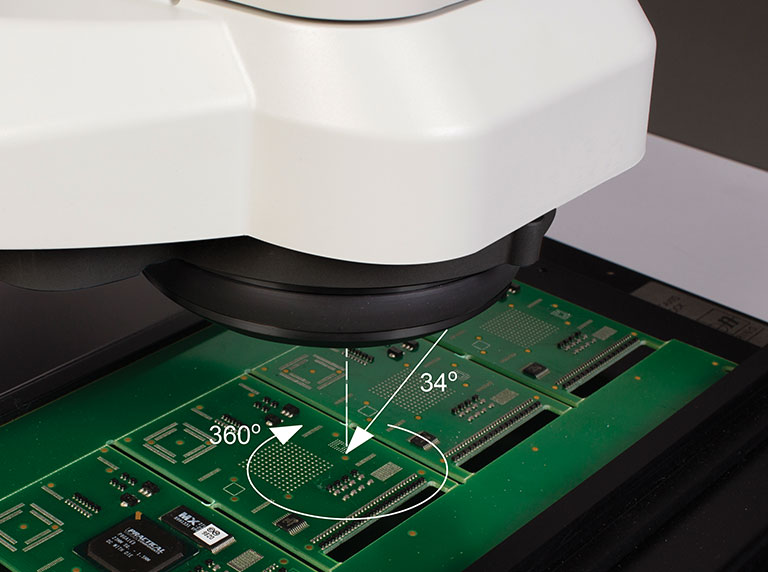

Inspect the sides of each lead or through any holes with a 360° viewer

Checking the quality of plating on PCB through holes or looking around and even under the leads (gull wings) of a Quad Flat Package (QFP) is made easier with the 360° viewer on Lynx EVO and EVO CAM. The 34° degree oblique view, which rotates 360°, around the center, allows quick visual inspection around the sides of a through hole or around each lead. Inspecting for solder quality, bridging, pad lifting, and other hidden defects is possible without the need for difficult manipulations of the board.

Faster goods inspection, documentation, and record keeping

Inbound quality control tasks are transformed with Mantis, Lynx EVO, and EVO CAM microscopes. Integrated circuits, ball grid arrays, dual flat no-lead, quad flat no-lead, unmounted components, and bare PCBs can all be examined in moments. Components used by third-party vendors should be inspected before the assembly process to prevent defects before production. Similarly, manufacturers of these components should inspect their products before they are shipped. Using a digital system for inbound and outbound inspection is a fast way to inspect and an ideal way to document any defects before and after production. Mantis PIXO, Lynx EVO, and EVO CAM are ideal for capturing high-resolution images that serve as valuable records for traceability, quality assurance, and compliance with industry standards.

To speak with one of our sales specialists to find the system best for your application contact us at 860.355.3776.

Popular inspection systems used in manufacturing electronics