Video Measurement System

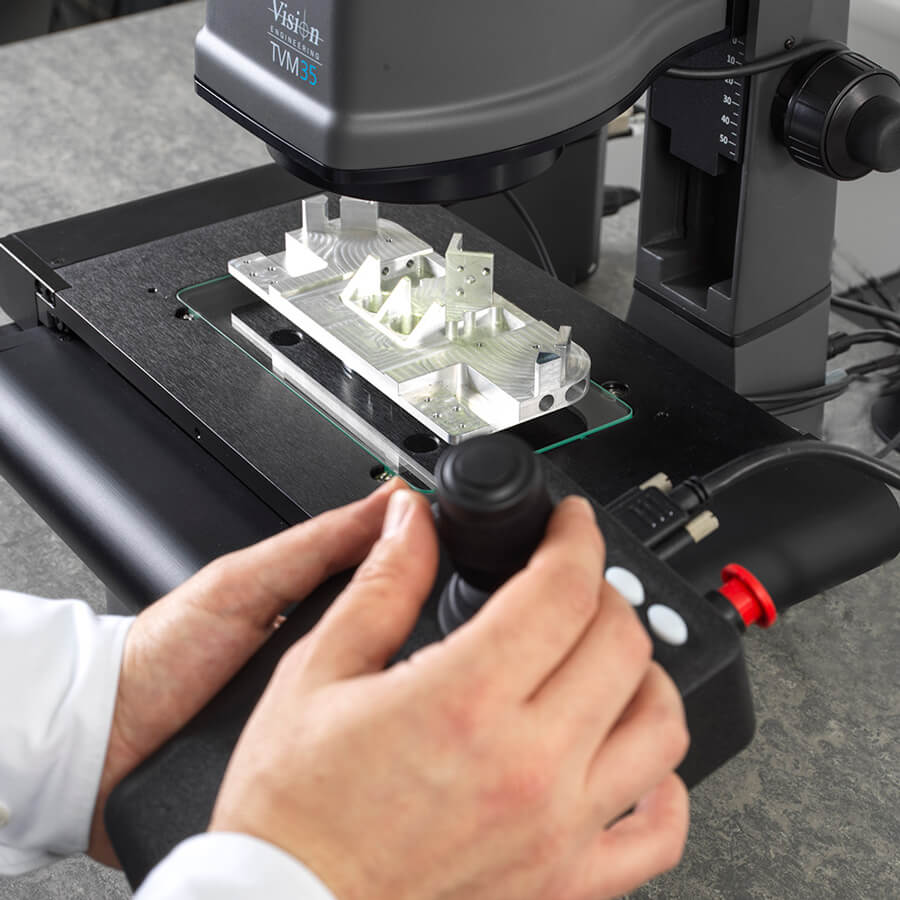

Measure any shape in an instant. If you need to measure parts and components quickly and in large numbers – regardless of their shape – you need a TVM20 or TVM35 video measurement system. All the operator has to do is place the subject on the stage for rapid measurement.

TVM is also ideal for taking 2D measurements of multiple subjects, when fast throughput and ease of use are essential requirements, and a great choice for a shop floor non-contact measurement system.

Large field of view for fast throughput

Thanks to TVM’s large 35mm field of view you can measure a wider range of samples in an instant. What’s more, a large depth of field means focus is maintained. You don’t have to waste time with fussy positioning or fixing: just place it, measure it, and move on to the next subject.

Measure larger objects with a motorized stage

TVM can be equipped with a motorized stage making it easy to measure objects which don’t fit into the field of view, offering much faster measurement than old style profile projectors.

Large

field of view (FOV)

Small

footprint

200 mm x 100 mm

CNC measuring stage

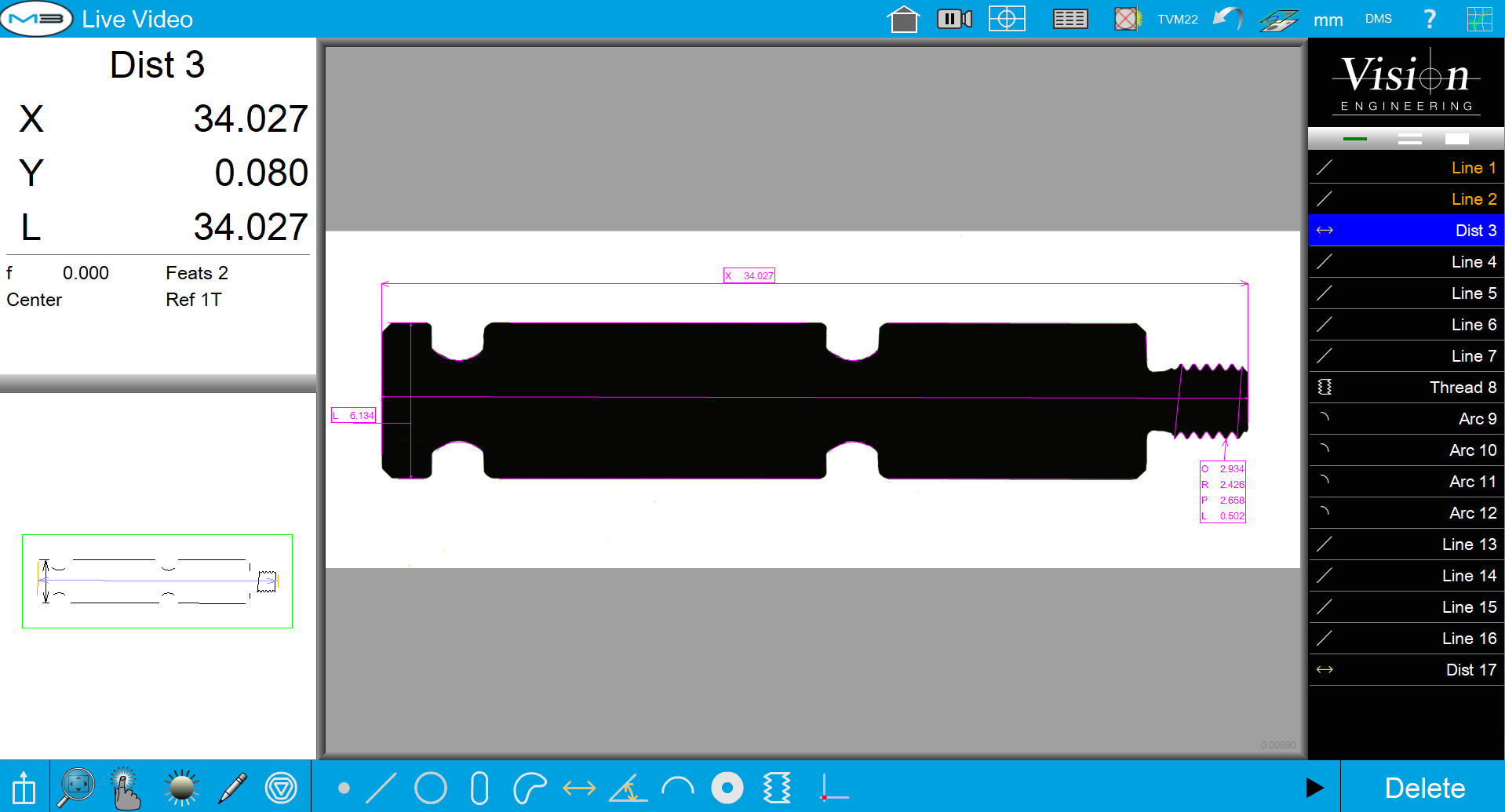

Sharp, flat image for improved edge detection

TVM video measuring systems use flat field telecentric optics and illumination to create a sharp image of the component on their HD monitor. The completely flat image across the full field of view, without any curvature or distortion, enables superior video edge detection capability for the accurate measurement and inspection of components.

A video measurement system that is easy to use

Everything about the TVM video measurement system is designed for ease of use. With minimal training and simple ‘place and measure’ functionality, measurements are instant and precise, and operator errors are eliminated. A large HD monitor displays a clear video image of the subject, and the richly-featured software gives you ‘Go/No Go’ simplicity with full geometric tolerancing, and reporting capabilities.