Coordinate Measuring Machines

Coordinate Measuring Machines (CMMs) measure the geometry of physical objects by sensing points on the surface of the object with a touch probe. They are used in manufacturing processes to inspect a physical part or assembly against the design specification.

When looking for a CMM, companies want a machine capable to withstand the elements associated with a shop floor environment since contamination and temperature changes effect measuring accuracy.

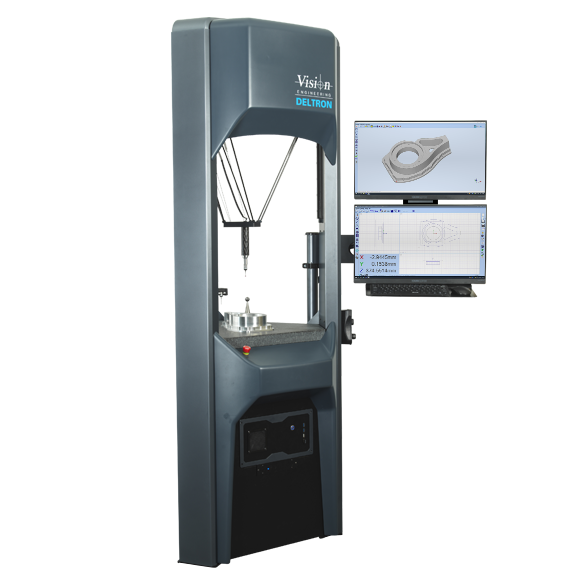

Deltron

DELTRON, designed with temperature sensors and fully sealed cross roller bearings for increased resistance against contamination, makes it ideal for placing it where it is needed.

Vision Engineering is moving shop floor CMM design forward with the new DELTRON. Features include a delta mechanism, small footprint, accurate and repeatable measurements and ease of use.

Find Out More

World-class innovation

Vision Engineering has been leading the world with pioneering technology and award-winning innovations since 1958. In 2020 we were recognized by the Queen’s Award for Innovation, for our Lynx EVO high magnification, stereo eyepiece-less microscope. Now and in the years ahead, we will maintain an unswerving commitment to innovation, ergonomic design and improved user productivity.

The Vision Engineering advantage

Everything that we make is designed with ergonomics and ease of use in mind. It’s what sets us apart. We know that if a microscope can be used comfortably, the operator will be happier and more productive. Accuracy, speed and throughput are all improved with Vision Engineering’s unique ergonomic designs.