Measuring within the field of view is a quick and accurate way to measure small components, providing unrivaled speed and simplicity compared to alternative methods such as profile projectors, video measuring machines, or measuring microscopes.

What is field of view measurement? How does it work and how could it help me?

What is Field of View measurement?

Field of view (FOV) measurement, or measuring within the field of view, is a rapid way to measure small components accurately, with amazing speed and simplicity. FOV measurement uses a specially designed high-resolution video camera to measure a component within the optical field of view.

FOV compared to alternative methods, such as:

Profile projectors – projects a magnified silhouette of a component onto a screen, with a measuring stage moving the component part so all of it can be measured.

Video measuring machines and measuring microscopes employ a magnified image, and similar to a profile projector it utilizes a measuring stage. Traditional optical measuring systems typically have a small field of view and rely on a stage since only a small area of the component can be seen by the optics at any given time. Moving the stage allows different parts of the component to be seen and measured.

|

|

|

| TVM 35 (21mm x 28mm field of view) |

Example 1x objective (14.2mm Ø field of view) |

Example 2x objective (7.1mm Ø field of view) |

Fig 1. Diagram illustrating the relative size of the field of view between a FOV system and an optical measuring system.

A larger field of view allows the whole component to be seen and therefore measured, without the need for a measuring stage, providing some significant advantages, including dramatically increased speed and unrivaled simplicity.

How does it work?

‘Flat-field’ optics

Field of view measurement employs a high resolution video camera, coupled with a large ‘flat-field’ telecentric lens system. The telecentric lens provides a flat image, across the full field of view, without any curvature or distortion, so you can place and measure your component anywhere within the field of view, without affecting the measurements.

|

|

|

| Fig 2. | Flat field of a telecentric lens | Curved field of a standard lens |

No need to focus *

Moreover, the ‘flat-field’ telecentric lens system has been designed with an exceptionally large depth of field, meaning your subject is always in focus*. Typically a depth of field (focus) with a comparable measuring device varies between a couple of microns and a couple of millimetres. Typically, a FOV measuring system has a depth of focus of 40mm or more (lens dependant).

*Note: Once the system is focused, no further focusing is required for components of similar height.

Why measure within the field of view?

A wide-field telecentric lens allows the whole component to be seen within its large field of view, enabling all the features to be measured in seconds. Compare this to alternative measuring systems, which require a mechanical stage to be moved to capture all of the measured points, therefore taking considerably longer. Not only can the whole components be seen and measured, but multiple components can be measured at the same time.

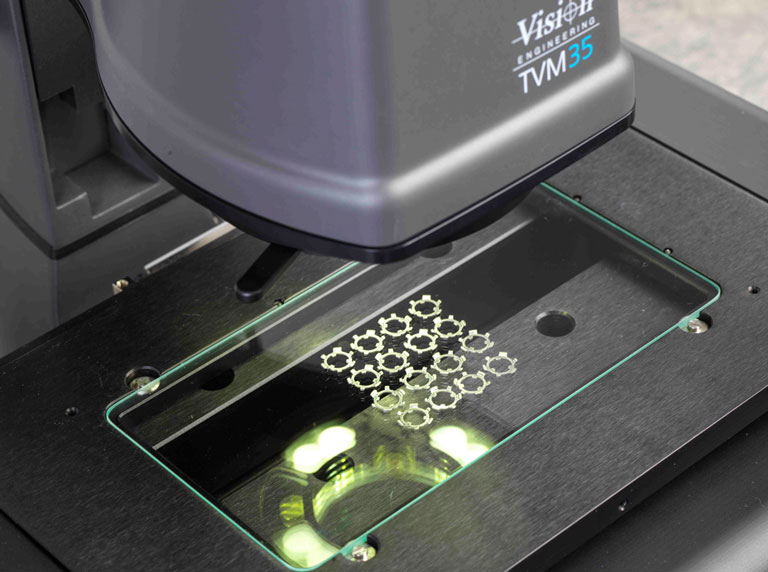

Fig 3. Single or multiple parts can be measured in seconds, using the same measurement program.

No moving stage required –

Since the entire component is ‘seen’ within the field of view, a moving stage to measure the whole component isn’t required.

The main benefits for FOV systems:

- No mechanical variance affecting the measurement results since there are no moving parts.

- No operator variance due to different habits or skills in taking the measurement.

- Measurement results are quick since there are no moving parts.

View whole components –

Benefits of viewing whole components:

- View and therefore measure all the visible ‘features’ in seconds.

- Measure multiple parts at the same time, saving you more time.

- No need to align or skew the part/s, saving you more time.

Simply place your part anywhere within the field of view.

Click the mouse to run since the software automatically recognizes the part.

All the features are measured in seconds.

What can I measure?

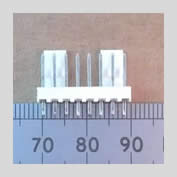

2D (X,Y) measurement within the field of view offers significant advantages over alternative dimensional measuring solutions. In order to benefit the speed and simplicity offered by FOV measurement, the major consideration is that your component must fit within the field of view (28 x 21mm). Typically, FOV measurement is ideal for 2D (X,Y) measurement of small parts, such as:

| Gaskets | O-rings | Stamped parts |

|

|

|

| Circlips | Pressed parts | Laser-cut / water-cut parts |

|

|

|

| Small plastic parts | Extruded materials | Cutting tools |

|

|

|

| Connectors | Other small flat parts | And much more … |

|

|

Full range of non-contact measurement solutions

Measuring applications vary greatly. Vision Engineering’s measurement range consists of both non-contact and contact measurement systems, ideally suited for a wide range of 2-axis and 3-axis measurement.

To discuss how the TVM or any Vision Engineering product can help save you time and money, contact one of our Metrology Application Specialists to discuss your measurement requirements.